Customer Type: Integrated Hygiene Solutions

Situation

Our customer’s existing IoT gateway faced cost, performance and obsolescence challenges. We were engaged to revise the design for use with both new and existing products.

The legacy system used a bespoke radio protocol, and a cellular link to communicate with their cloud service. New product concepts on the horizon were expected to use the same equipment in due course.

The revised design must operate as a drop-in replacement, with performance and reliability enhancements that match or exceed the current offering. Care must be taken to reduce impact on existing enclosure tooling and assembly processes.

Approach

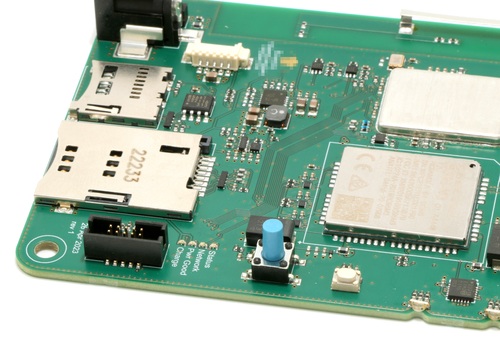

Tasked with revising one of the device’s two PCBs, after careful review we proposed a full redesign, allowing for smaller electronics, simpler assembly and further cost reductions. This would also reduce the custom firmware count from three to just one.

Ensuring reliable message delivery was vital – the gateway must “buffer” messages if the cloud service was ever unreachable. The device must also be fully operational for at least 24 hours without mains power.

Limited radio protocol documentation was overcome by reviewing firmware sources and analysis of radio signals. Components were selected, and compatibility was quickly confirmed with off-the-shelf development tools.

Implication

The full electronics redesign allowed for a number of opportunities – such as a hidden requirement to remove all external antennas. The selection of new components also allowed us to offer use of the LoRa radio protocol with our customer’s new products, a follow-on project which we have since completed and included the design of a radio protocol and HTTP API.

We took the project from the initial requirements capture, through design, prototyping, development, and EMC & Radio Compliance testing. Afterwards, we supported hand-off to our customer’s Contract Manufacturer for production, and supported with design and development of a test jig and associated production-line tools.

Outcome

The new gateway design was tested, found to exceed the customer’s original operational scope of requirements, and was verified as a direct drop-in replacement.

Since completion of the original project, we have offered support and services for a number of extensions and modifications to the device. One such extension is the development of a LoRa-based system for a new line of products, paired with the associated compliance re-testing.